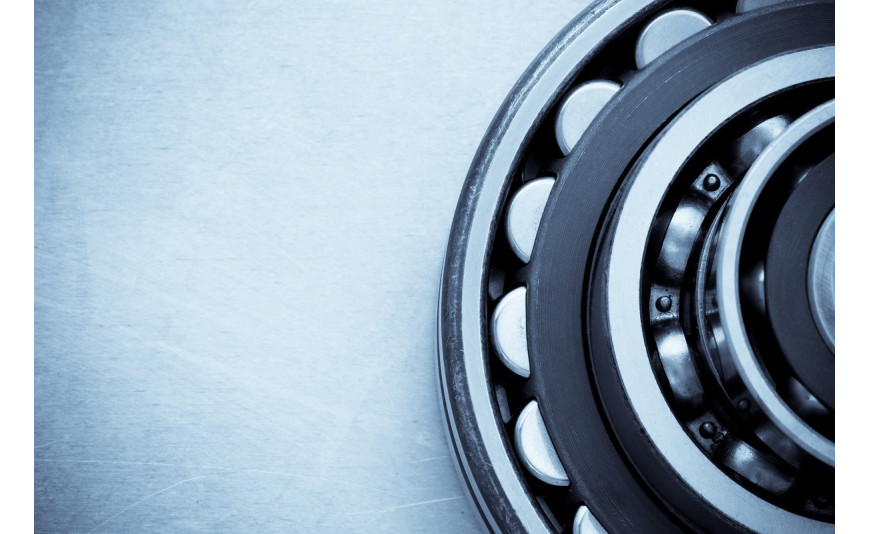

Different types of bearings - from ball bearings to roller and inch bearings.

- 08 Mar, 2024

- Home

An overview of different types of bearings: ball bearings, roller bearings, including metric and inch sizes, highlighting their key features and potential applications. We invite you to read on!

Basics of Bearing Knowledge

In the world of mechanics, ball bearings and roller bearings play key roles. Being an integral part of many machines and devices, they enable smooth and efficient operation.

Ball bearings are one of the most popular types of bearings. They feature a special groove in which balls are placed. This allows objects with a diameter larger than that of the balls to move, enabling rotational movements. Ball bearings are used in many industries - from automotive to agriculture and even aerospace - due to their durability and ability to carry both radial and axial loads.

Roller bearings are another type, where the rolling elements are rollers with high resistance. They have wide applications where there is a need to transfer large loads with high precision. Roller bearings offer higher stiffness due to their design and can carry greater loads compared to ball bearings.

Application of Bearings in Industry

Automotive bearings and self-aligning bearings in housings are essential components in many branches of industry. Automotive bearings play a crucial role in the automotive industry, enabling smooth and durable operation of vehicles. They are primarily used in suspension systems, gearboxes, wheels, engines, and pumps. Thanks to them, vehicles can move while maintaining stability and safety, as well as increasing their lifespan and efficiency.

On the other hand, self-aligning bearings in housings are used in many sectors where long-lasting and uninterrupted operation under constant load is necessary. They are used e.g. in the machine, construction, agricultural, and processing industries. Due to their design, they can be autonomous and self-adjusting, which contributes to their high durability and ability to work in various conditions. Their housing allows for easy and quick installation, and a wide range of sizes makes them highly versatile.

Types and Characteristics of Needle Bearings

Needle bearings are another category, whose unique characteristics determine their specific applications. They are constructed so that the rolling elements are in the form of elongated "needles," hence their name. This makes needle bearings exceptionally slender and compact, making them ideal for situations where space is limited.

The advantage of needle bearings is their ability to carry high loads despite their small size. This makes them suitable for use e.g. in the automotive, machinery, or aerospace industries. Needle bearings, like other types of bearings, play a fundamental role in ensuring smooth and efficient operation of machines and devices. Their specificity makes them an ideal solution where efficiency and space savings are required.

Construction and Functions of Roller Bearings

Roller bearings are a specific type, whose construction is based on cylindrical rolling elements called rollers. These precisely manufactured parts allow for low internal friction, and consequently, higher work efficiency. The construction of roller bearings is varied - the basic types that stand out include single-row, double-row, four-row, or full roller bearings. Each has its unique characteristics and dedicated applications.

The main advantage of roller bearings is their ability to carry large radial loads. This is achieved due to the larger contact area between the raceways and the rolling elements. Their application is broad, covering the automotive industry, machinery industry, and extending to heavy industry applications. It is particularly worth noting that:

- in the automotive industry, they are used to service various components such as gearboxes and axles,

- in the machinery industry, they are used in places where structural considerations require the use of high-load bearings,

- while in heavy industry, they are used to service equipment operating under heavy loads.

Regardless of the place of application, cylindrical bearings offer high efficiency and reliability, making them an indispensable element in many industrial sectors.

Guide to Angular Contact Bearings

Another important element in the industry is angular contact bearings. Their design has been created to transfer combined loads, i.e., radial and axial loads. The construction of angular contact bearings is somewhat more complex than that of ball or cylindrical bearings. Due to the angle between the raceways, which is inclined, hence their name, they can transmit both radial and axial loads. Importantly, this is only possible in one direction, which is why they are often used in pairs.

Angular contact bearings have wide applications in many branches of industry, including automotive, machinery, and construction industries. They are an integral element of many machines and devices, such as spindles of machine tools or axles of trucks. By taking care of their proper operation and maintenance, one can count on their long service life and high level of performance. Due to their specificity and unique properties, angular contact bearings are excellent where other types of bearings may not meet the demands.

Choosing Bearings for Specialized Applications

Selecting the right bearings for specialized applications requires an understanding of the specific loads and working conditions in which they will operate. In specialized applications, an important factor is the range and type of load, as well as determining whether it is radial, axial, or combined. This is where cylindrical bearings and needle bearings come in, which perform excellently in various specialized applications.

Cylindrical bearings can carry large radial loads due to their construction. As a result, they are often used in heavy industry. On the other hand, needle bearings, due to their slender and compact size, perform excellently where space is limited, while still offering the ability to carry high loads. However, it should be noted that both cylindrical and needle bearings require regular maintenance and proper installation to achieve maximum efficiency and longevity. When choosing bearings for specialized applications, it is advisable to consult your choice with experts in the field to ensure the optimal solution for a specific application.

Maintenance and Replacement of Automotive Bearings

Proper maintenance and replacement of automotive bearings are essential to ensure the long-lasting, trouble-free operation of the vehicle. Regular inspections will allow for the early detection of potential problems. Particular attention should be paid to symptoms such as unusual noise, vibrations, or brake operation. In the event of damage, the replacement of automotive bearings should be carried out as soon as possible to avoid further, more serious problems with the vehicle. It is worth remembering that bearings are components that bear heavy loads, so their proper functioning affects the overall performance and safety of driving.